Servicing the Aerospace, Commercial and Medical industries from Milford, Connecticut.

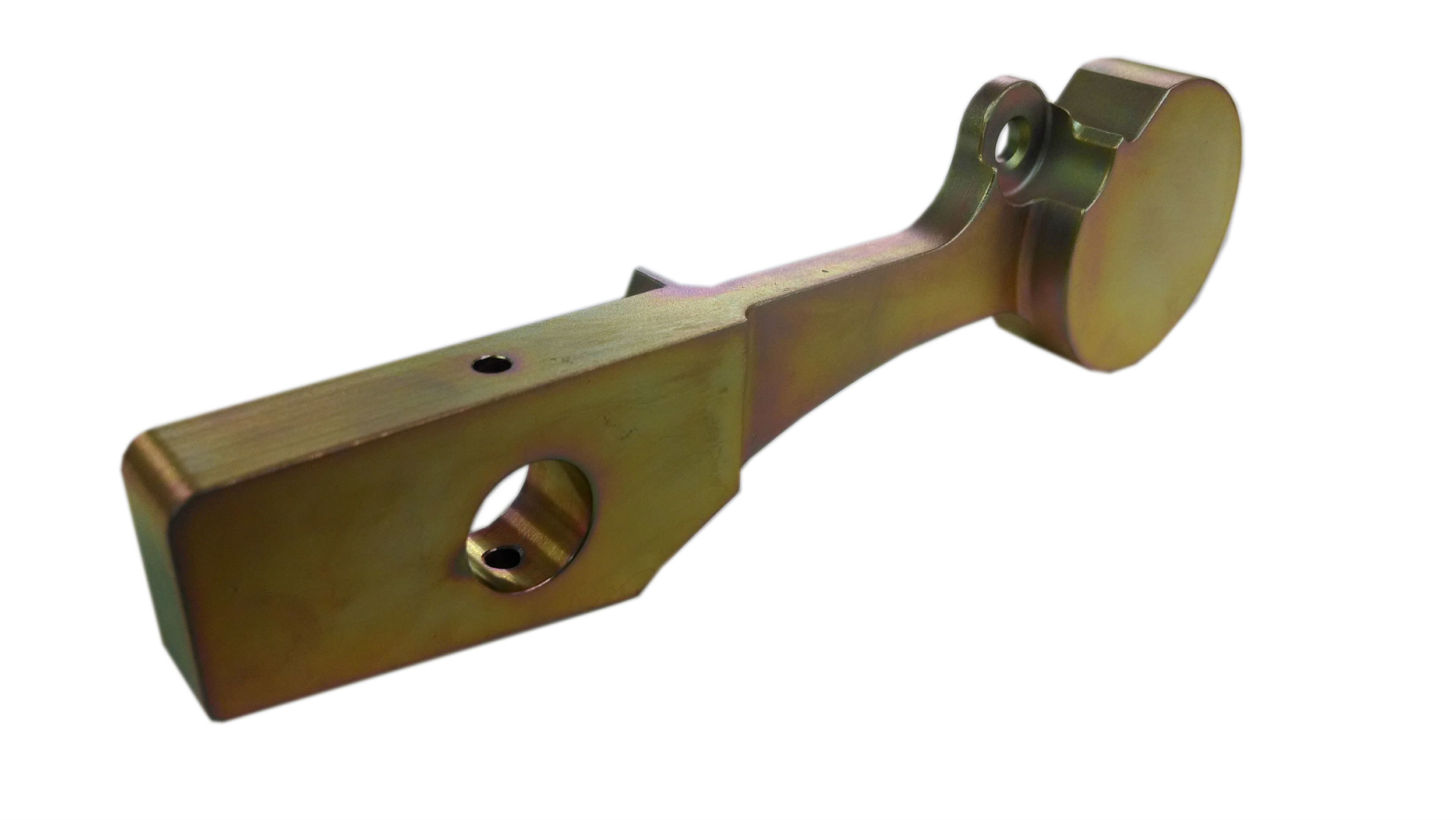

Computer-aided Design and Computer-assisted Machining (CAD/CAM) is our specialty. Together with our large and well-established supplier base here in New England, we can bring your ideas to life from prototype to production.

We also have a large inventory of Sikorsky aircraft spares available for immediate purchase. Contact us to see what's on our storeroom shelves.